Toyota total quality management system. Discussion about Total Quality

Toyota Motor Co., Ltd. started at the beginning of 1949 a preliminary investigation for statistical quality control with the Machining Plant as a model factory. The following year, the company moved into more proper study in January 1950 and quality control of machining parts was begun.

💌 Toyota quality management process. Toyota Quality Management. 20221028

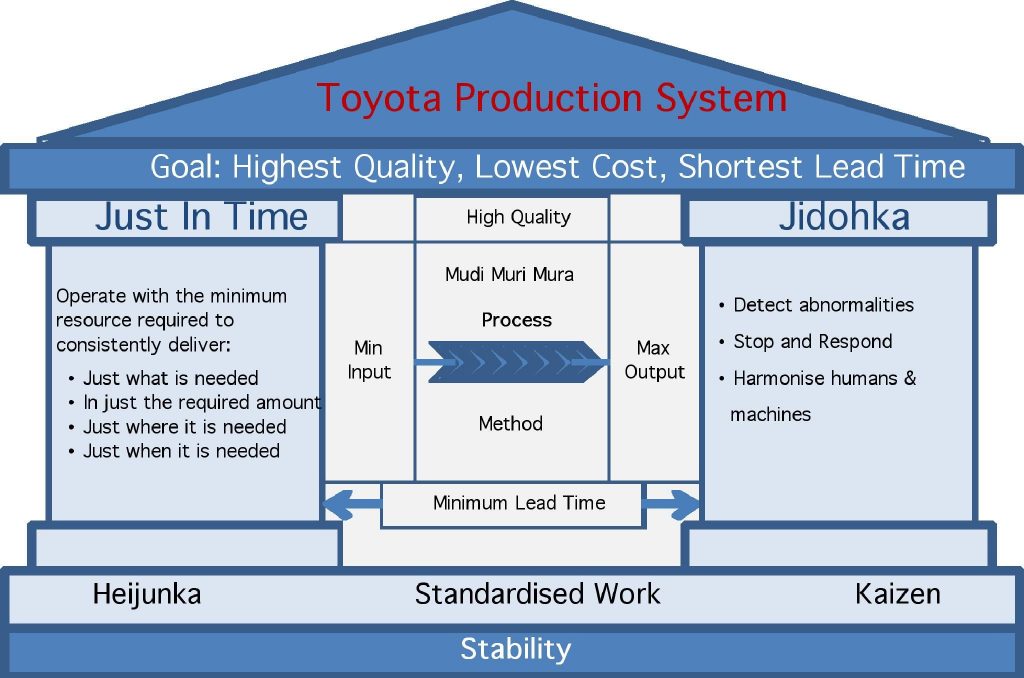

1 Customer expectation determines the quality required. 2 Quality is built in at every stage of the process. 3 Quality is continuously improved (kaizen) The three Quality Principles define our Quality Policy. TMUK Quality Policy The aim of Toyota UK is to achieve Customer Satisfaction in all activities.

Qc process chart toyota

For many years, the Toyota Motor Company was widely considered to be a leader in quality management. Based partly on this reputation and the perceived quality of its products, the company.

Toyota Driving Innovation and Quality to the Next Level • HamroSaathi

Quality Is a Key Management Issue Toyota Industries' founder Sakichi Toyoda once said that "A product should never be sold until it has been carefully manufactured and tested thoroughly and satisfactorily". Adhering faithfully to his teachings, Toyota Industries believes quality is our lifeline and a key management issue.

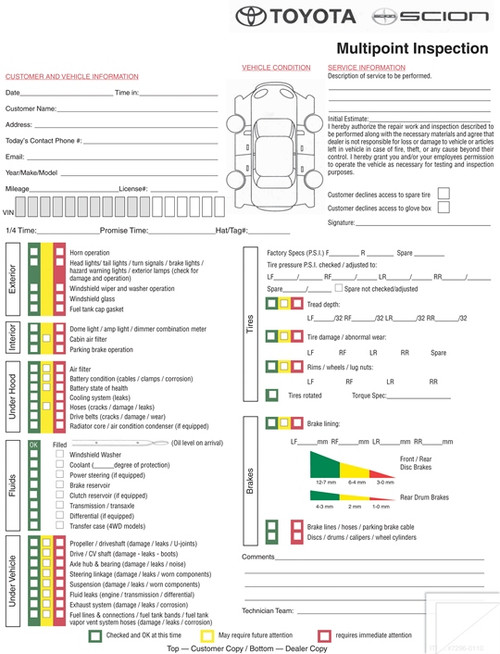

Toyota Quality Vehicle Inspection Forms

TOYOTA MOTOR CORPORATION (TMC) announced that it held a ceremony today to mark the 20th anniversary of the Toyota Global QC Circle Convention, an annual event that showcases voluntary quality-improvement initiatives of Toyota workplaces worldwide. TMC President Katsuaki Watanabe and other representatives attended the ceremony, held at the TMC head office in Toyota City, Aichi Prefecture.

🔥 Toyota total quality management system. Toyota's Management System

But Toyota had built much of its reputation on keeping tight control over quality. In an attempt to end the affair, Toyota is expected to pay a stunning $1.3 billion to compensate owners for economic losses associated with its cars. The terms of those settlement agreements keep all discovered technical facts secret.

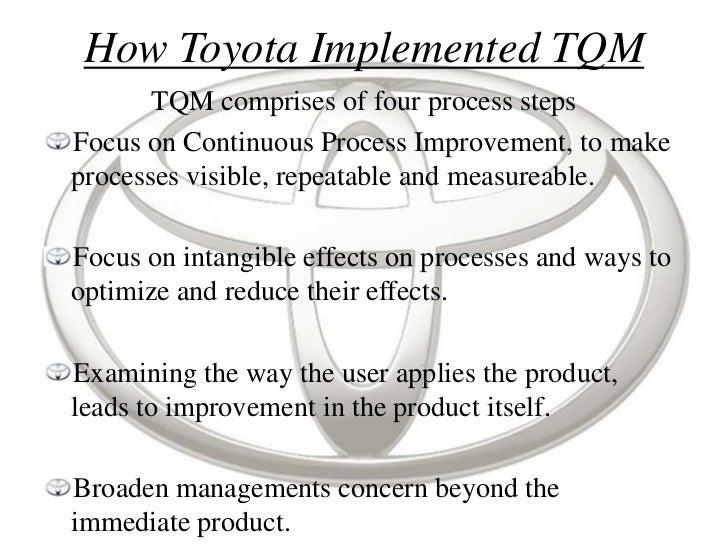

How Toyota Maintains 99.9999 Quality Toyota Quality Management

Total quality control is carried out using two basic principles: quality is built in at every stage and quality is continually improved. To achieve total quality control Toyota Manufacturing UK involves each and every Member to ensure that only the best work is passed on to the next process.

Science TQM, New Quality Management Principle The Quality Management

Fundamental Approach The origins of Toyota's "Customer First" and "Quality First" principles lie in the Five Main Principles of Toyoda, which embody the thinking of Sakichi Toyoda, and the spirit of audit and improvement of Kiichiro Toyoda.

💌 Toyota quality management process. Toyota Quality Management. 20221028

Quality at Toyota means minimising customer inconvenience and applies not just to products, but also to the quality of work we do in all our business areas.

N.A. gets a key role in Toyota quality control

The recall is already having an impact on Toyota's business results. On February 2, the company reported a 16% decline in sales to a 10-year low of 98,796 vehicles. At the same time, General.

Received the Quality Control Excellence Award from Toyota Motor

Chart 1. Toyota Industries' founder Sakichi Toyoda once said that "A product should never be sold until it has been carefully manufactured and tested thoroughly and satisfactorily". Adhering faithfully to his teachings, Toyota Industries believes quality is our lifeline and a key management issue. Maintaining and improving quality is our.

Toyota Producing Quality Quality assured in every vehicle

Executive Vice President, Product Support & Chief Quality Officer, Toyota Motor North America; Chris Nielsen is executive vice president of product support and chief quality officer for Toyota Motor North America (TMNA). In his role, Nielsen oversees a number of functions including: purchasing and supplier development, quality, supply chain.

Toyota Quality System Toyota Blog

The judges concluded that Toyota had achieved visible results in maintaining and improving quality through its promotion of company-wide initiatives. They outlined Toyota's achievements as follows. 1. Toyota has further improved control activities in each department by building on efforts made when it was first awarded the Deming Prize. 2.

😂 Tqm process of toyota company. Total Quality Management information

Management. Total Quality Management (TQM) Changes and Innovations. History of TQM. Management and Finances. Management. Business Objectives

Toyota total quality management system. Discussion about Total Quality

Quality Quality Assurance Activities Since its founding, Toyota has steadfastly carried out quality assurance activities, resulting in top ratings from our customers.

Toyota Mirai 2015 il Quality Control YouTube

Toyota establishes the rules, methods, and criteria necessary for controlling its manufacturing and business processes to enable Toyota to continuously provide the product performance and functions, as well as services, that Toyota aims to achieve.